In industries like aerospace, defense, and commercial engineering, precision isn’t just a requirement—it’s an expectation. Every component, down to the smallest detail, plays a critical role in ensuring safety, functionality, and performance. This is where precision CNC machining becomes indispensable. Let’s explore why it’s the cornerstone of these sectors and what makes it a trusted solution for advanced manufacturing needs.

Precision at the Core of Aerospace Engineering

When it comes to aerospace, even the slightest deviation can lead to catastrophic consequences. Aircraft components must meet stringent tolerances to ensure:

- Safety: A minor error in machining could compromise structural integrity.

- Efficiency: Lightweight yet durable parts are crucial for fuel efficiency and performance.

For example, turbine blades, often made from high-strength alloys, require intricate machining to meet exact specifications. CNC machining ensures repeatable accuracy, making it the go-to choice for aerospace manufacturers.

Defense Sector: Where Reliability is Non-Negotiable

In defense applications, durability and precision are vital. From armored vehicles to missile systems, every part must perform flawlessly under extreme conditions. CNC machining offers:

- High Tolerance Levels: Essential for components in firearms, guidance systems, and surveillance equipment.

- Material Versatility: The ability to work with advanced materials like titanium and composites ensures durability without compromising functionality.

Think of CNC-machined parts as the silent heroes—ensuring equipment operates smoothly when it matters most.

Transforming Commercial Engineering

Commercial engineering spans a wide range of industries, from automotive to robotics. Here, precision CNC machining drives innovation by delivering:

- Customized Solutions: Unique designs for specific applications, such as automotive prototypes or industrial automation components.

- Scalability: Efficient production processes ensure consistency, whether for small batches or large-scale manufacturing.

For instance, CNC machining enables the production of gear systems and intricate parts that power modern machinery, helping businesses stay competitive in a rapidly evolving market.

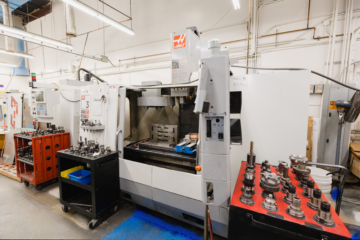

How CNC Machining Meets Industry Challenges

Industries like aerospace and defense operate under constant pressure to innovate while adhering to strict standards. CNC machining addresses these challenges through:

- Automation: Advanced CNC machines minimize human error, improving reliability.

- Adaptability: From 5-axis machining to multi-material processing, CNC solutions keep pace with technological advancements.

- Cost-Effectiveness: Despite its precision, CNC machining reduces material waste and increases efficiency, saving costs in the long run.

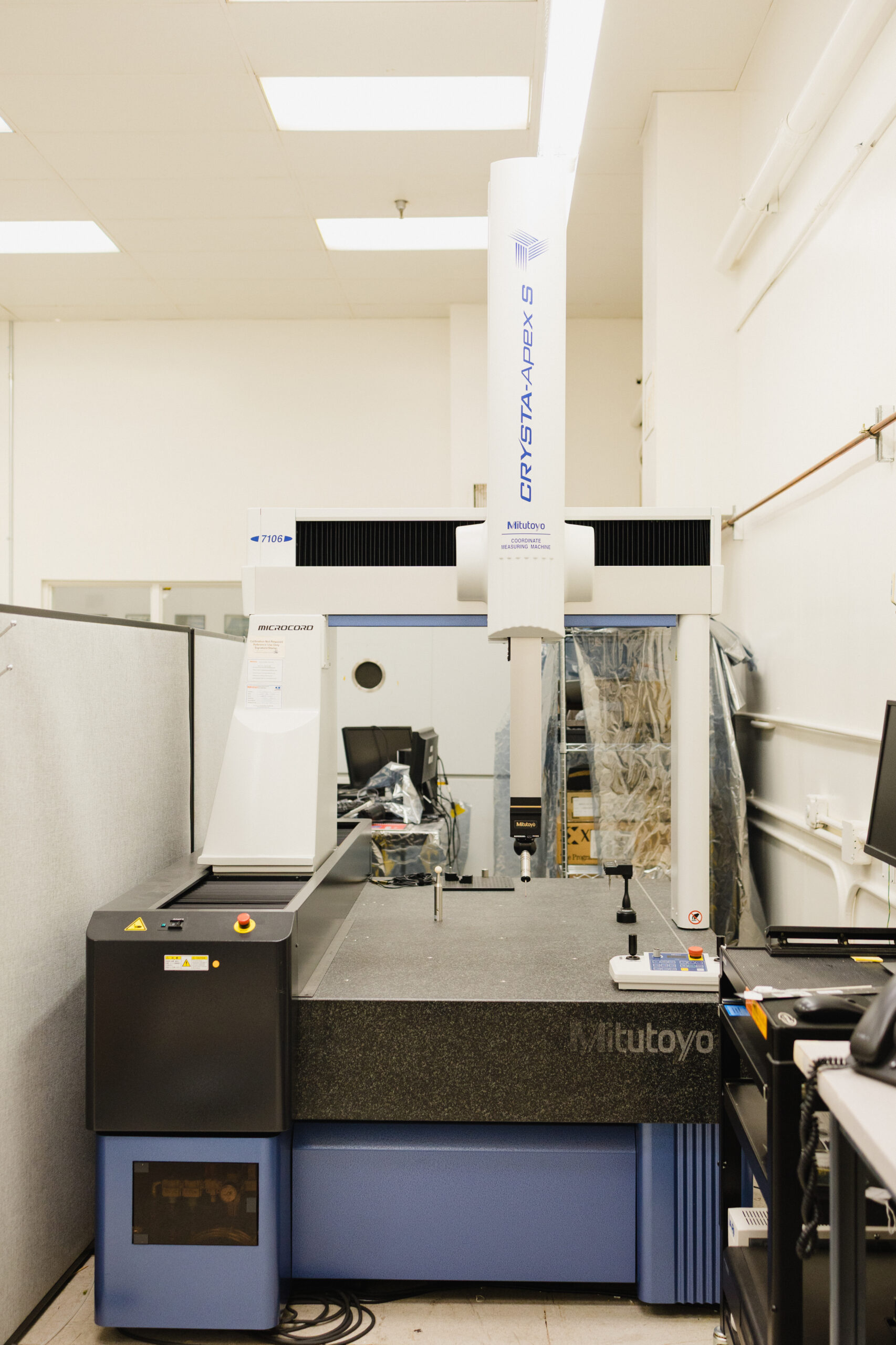

Trust and Experience: The Role of a Reliable CNC Partner

Choosing the right CNC machining partner can make all the difference. Experience, combined with state-of-the-art technology, ensures that:

- Critical Deadlines are Met: Essential for fast-paced sectors like defense.

- Quality is Uncompromised: Precision machining isn’t just about meeting specifications—it’s about exceeding them.

At T&M Machine Shop, Inc., we bring over 30 years of expertise in high-precision CNC machining, fabrication, and assembly services. Our commitment to quality and innovation has made us a trusted partner in aerospace, defense, and commercial engineering.

Conclusion: Precision for Progress

Precision CNC machining is more than a manufacturing process—it’s the foundation of progress in industries where failure isn’t an option. From the skies to the battlefield to everyday innovations, the impact of CNC machining is undeniable.

If your project demands unmatched accuracy and reliability, trust the experts. Contact T&M Machine Shop, Inc. today to discuss your needs and discover how we can bring your vision to life.