Quality at T & M Machine Shop: Precision, Compliance, and Excellence

At T & M Machine Shop, quality isn’t just a requirement — it’s a commitment. Our relentless pursuit of precision, reliability, and compliance drives every project we undertake. From material sourcing to final inspection, each step in our process is designed to ensure exacting standards that align with industry best practices and regulatory requirements.

Our Approach to Quality

At T & M Machine Shop, quality assurance is embedded into every stage of production. We combine advanced manufacturing capabilities with a rigorous quality control system, ensuring flawless execution from prototype to production.

Advanced Inspection & Quality Control

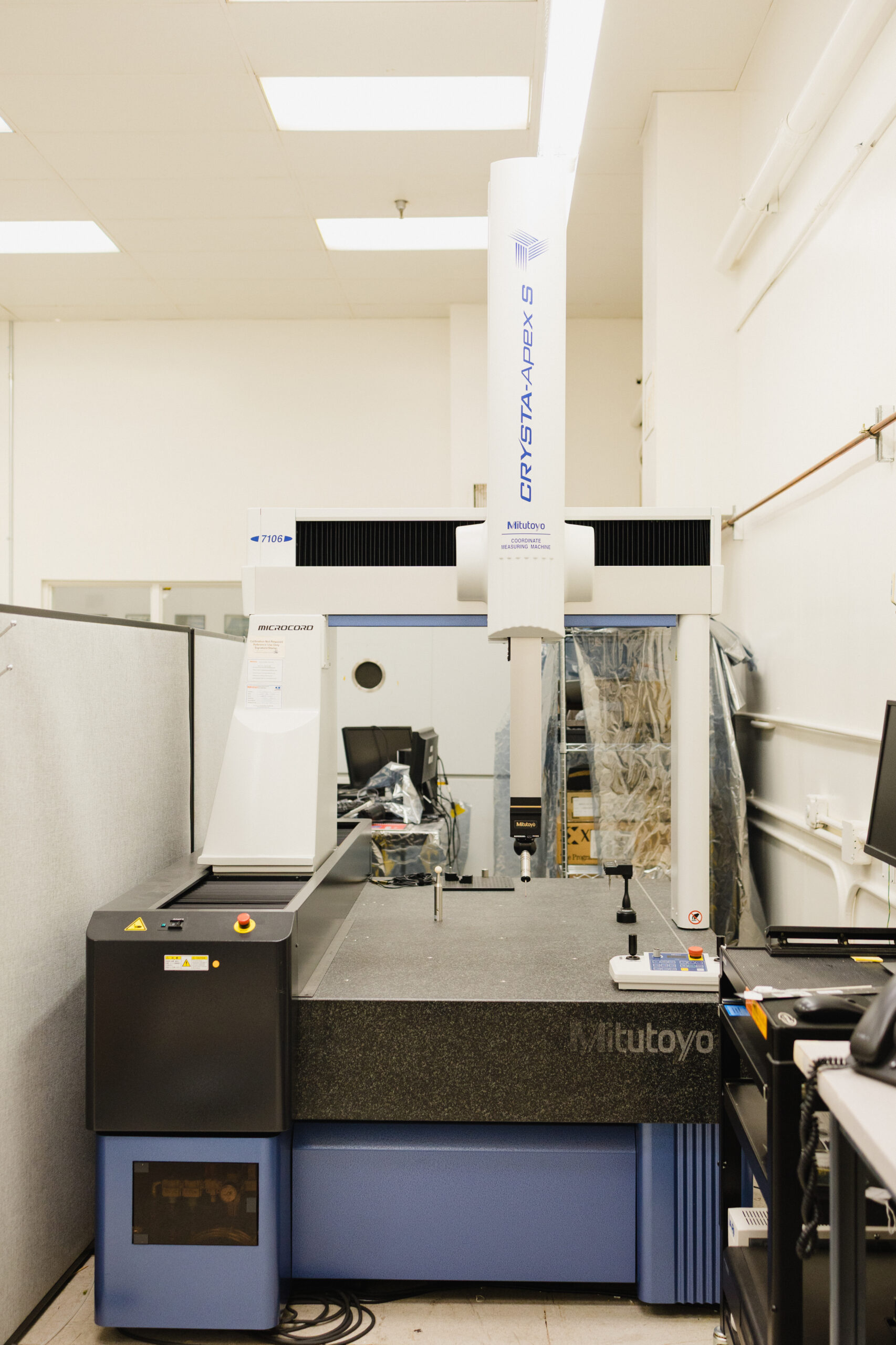

- CMM (Coordinate Measuring Machine) Inspections: Our Swiss-made high-accuracy CMM ensures that components meet precise dimensional tolerances.

- In-Process Inspections: Parts are continuously monitored during machining to identify issues in real time.

- Final Inspections: Comprehensive inspections ensure compliance with design specifications, using a suite of calibrated calipers, micrometers, and gauges.

Certifications & Industry Standards

To maintain our position as a trusted manufacturing partner, we adhere to a broad range of certifications and industry standards that reflect our commitment to quality and compliance.

Current Certifications & Compliances:

- ITAR Compliance (ITAR 40004)

- DFARS Compliance

- GD&T Proficiency

- GR&R (Gage Repeatability & Reproducibility)

Certifications In Progress:

- ISO 9001

- ISO 13485

- AS9100

- Nadcap

- FDA Compliance

Quality Control Methodology

Our Quality Control (QC) methodology is designed to ensure traceability, accountability, and precision. We employ robust checks at every stage of production, from material procurement to final inspection. Our approach includes:

First Article Inspection (FAI):

Rigorous inspections during initial production runs to confirm process capability.

Statistical Process Control (SPC):

Data-driven methods to monitor and control production quality.

Gage Repeatability & Reproducibility (GR&R):

Ensuring the accuracy and consistency of our measurement instruments.

Traceability:

Full material traceability, providing detailed records for each project from start to finish.

Equipment & Tools for Quality

Our quality team operates with world-class inspection tools to ensure accuracy and precision. Our facility is equipped with:

- Swiss-made Coordinate Measuring Machine (CMM): Industry-leading precision for dimensional validation.

- Calipers, Micrometers & Gauges: Comprehensive suite of calibrated tools for dimensional checks.

- Dedicated Inspection Lab: Climate-controlled inspection area for optimal measurement accuracy.

Our Registrations & Industry Identifiers

T & M Machine Shop maintains formal registrations and industry identifiers that validate our role as a trusted partner in high-precision manufacturing.

- NAICS Code: 332710: Classification as a precision machine shop.

- CAGE Code: 4DG25: Unique identifier for companies that supply the U.S. Department of Defense and other government entities.

Quality Without Compromise - Partner with T&M Machine Shop

When you work with T & M Machine Shop, you’re choosing precision, accountability, and uncompromising quality. Our proactive quality assurance system ensures that every component meets your exacting standards, no matter the complexity. Contact us today to learn how our quality-first approach can elevate your next project.